Applications

Most of our customers only need small batches of 10 to 500 units per year, which often can be realized by customizing our stock hardware. After the initial series and testing the functionality we can also develop a fully customized hardware which is exactly tailored and optimized according to our customers‘ needs.

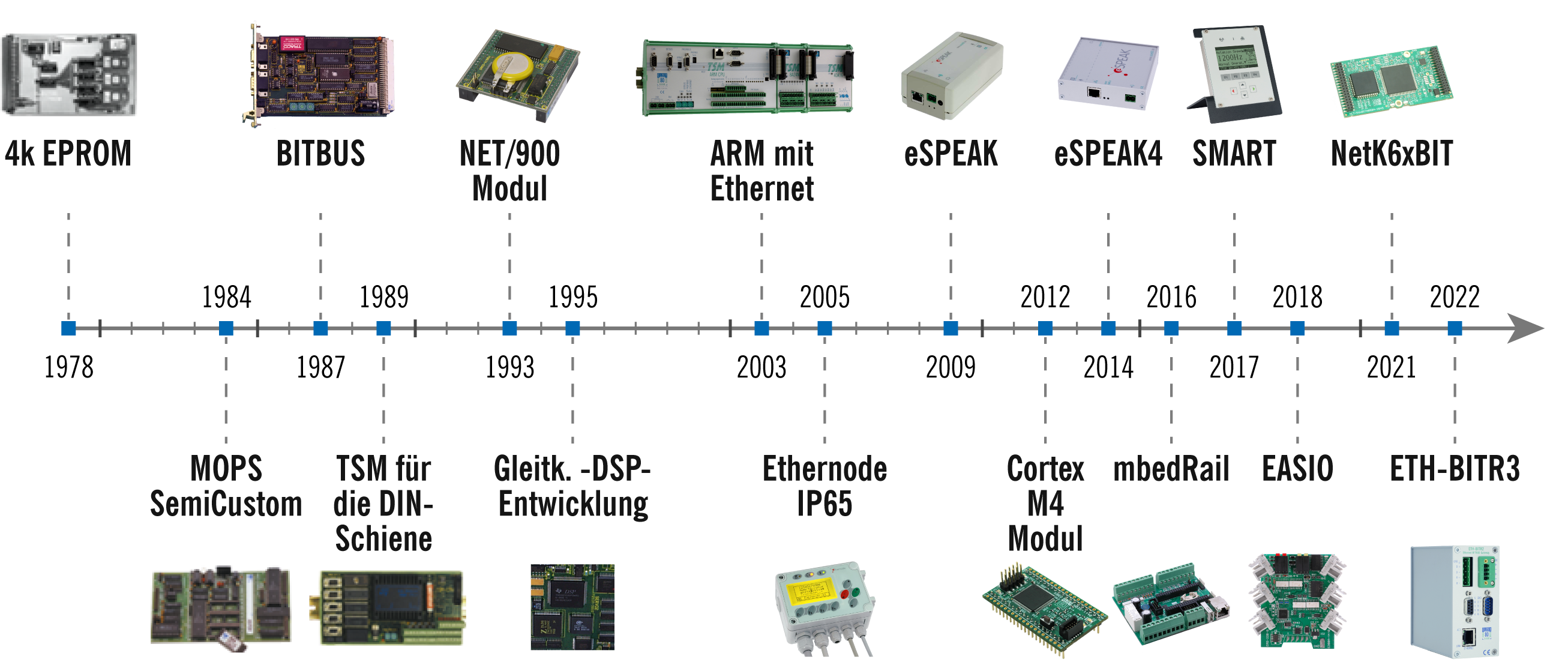

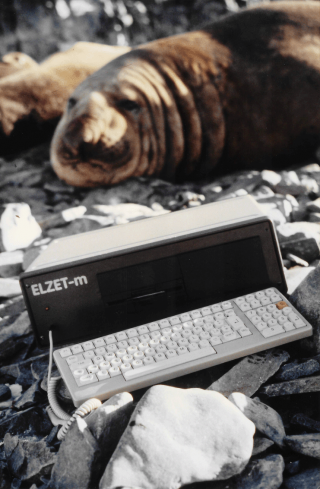

Throughout the years, ELZET 80 products have been present in the development of several innovative projects. For over 45 years we have fullfilled our customers wishes as flexible as possible. That is why our customers can directly call our professional employees.

In this section we would like to show the applications of some of our customers:

Smart Data Device

RWTH Aachen University - Aachen, Germany (Smart Data Device)

In line with the future vision of Industry 4.0, we partnered with the Institute of Automatic Control (IRT) from RWTH Aachen University in the Smart Data Device (SDD) project, to research methods for improving the degree of digitization in the field of production and process engineering. The project is funded by the Federal Ministry for Economic Affairs and Energy (BMWI) under the Central Innovation Programme for SMEs (ZIM).

With the aim of operating production and process plants in a more resource-saving and efficient manner in the future, while at the same time facilitating access to intelligent control, a self-optimizing control system is being developed in this project. Specifically, adaptive model predictive control (MPR) will be implemented on a microcontroller (Smart Data Device). The programmable logic controllers (PLCs) currently used in many existing plants often do not have the capabilities or sufficient computing capacity to implement higher-order control methods. In order to avoid production downtime due to replacement of the control hardware, the infrastructure of the existing plant control system is therefore to be retrofitted with the SDD. Above all, this enables the implementation of adaptive, process data-based model predictive control.

Ink supply in rotary printing

Müller Tankanlagen - Hamburg, Germany.

Here TSM is used in an ink supply unit for magazine printing machines. This unit was developed by Müller Tankanlagen from Hamburg for a machine with 8 printing units. One TSM at each printing unit; all connected to the control station with RS485.

Garbage sorting

Tomra Systems GmbH (before TiTech VisionSort GmbH) - Koblenz, Germany (TSM und DinX)

TiTech VisionSort GmbH has developed a system using near infrared (NIR) detection to sort garbage for recycling. The NIR camera delivers its pictures to a PC serving as evaluation unit which detects the position of materials that are to be sorted out. TSM is used to switch magnetic valves that release compressed air and blow the plastic objects from the conveyor belt. Less time critical function in this system are controlled by DinX.

Analysis automat

SEAL Analytical (before: Bran + Luebbe) - Norderstedt, Germany (NET/900H)

The motherboard of this analysis automat from SEAL Analytical, is equipped with high precision ADCs, special analog ICs and device specific power drivers. A NET/900H module is also on that board.

Connection to the processing PC is made via Bitbus or RS232. Time critical programming is facilitated by the mCAT real-time core.

Handterminal

ANDRAS System - Bremen, Germany (NET/900)

For use in a small hand terminal the motherboard has to be adapted to the case shape. This unit for ANDRAS System in Bremenhas integrated voltage supply for LCD, a socket for the LCD-graphics-controller and a floppy controller.

Digital motor controller

ANDRIVE - Bremen, Germany (Custom Application)

A particularly impressive application of the DMCUs from ANDRIVE is the submarine cable winding machine. More than 200 BITBUS-networked IP65 drive units move 102 1,2t coils, so that only very little force pulls at the cable while the two-layer steel wire cable armor (5mm) is put onto the cable. The central control unit is a TSM-CPU.